Working in the boot at the moment,

First job was to clean up the bonding between the boot compartment floor / wheel wells and the body, then refill a few joints and seal.

Next, mounted the Boot Lid on its hinges and put on the car to line up gaps, the left side gaps need opening up a few millimeters to get the handle and latch central.

There is a cross brace from side to side of the wheel arches which have the boot hinge mounts integrated. Everything lined up well with minimal adjustment. Machined up some spacers for the hinge joint so it locates same place each time its removed

Next was the mounting of the number plate lamp and plate mounting bracket.

The lamp came from Finishline Accessories, the Plate bracket was a local stainless part from Snakebite when they were in existence. It was sized perfect for the lamp, but didn't fit on the body well sitting 5mm higher than the boot lamp location. The bracket interfered with the lip below the lamp mount. After looking at how to modify the bracket neatly, I decided it was easier and neater to file off the lip on the boot for a much cleaner finish.

The task of hiding the number plate wire between the inner and outer lining and getting it to route from the hinge end to the number plate location was the challenge with a piece of bent brazing rod with a hook on the end of it, once I sited it at the hole, grabbed it with the pliers, hooked on the wires and dragged it back through the boot lid.

I'm using 10mm quick release Hitch Pins to mount the boot as well, same as the bonnet.

To remove, I still have to unbolt the gas strut, but wont need to wrench under the boot area.

As with the bonnet, I can remove and replace correctly very easily.

Once the boot sat aligned, mounted the boot lock handle and latch.

The latch pin was about 10mm too low to engage with the hook so made up a spacer to place under the latch pin bracket.

Last job was to mount the gas struts, 2x 315mm 200n Struts are provided by CR with mounting brackets for riveting or screwing to the boot floor, The struts locate to the hinges.

The struts take up usable space in the boot area, so I made a bracket that fits to the roll bar tube lower mount on the drives side and replace the two supplied 200n struts with one 400n strut. Finished with a much neater strut location and working perfectly with the boot lid becoming strut assisted from about 100mm of lift to fully opened.

I've decided not to line the entire boot area and have made a mat only for the floor, the boot walls look clean and came up well after coating with bed liner spray paint.

The floor also has 2x 80/20 low profile 1575 series extrusion mounted on it, this triangulates from the Tow Bracket location on the rear Chassis Cross Bar back to the original specified Roll Bar Hoop Third Leg mounting point on the chassis adding strength to the Tow point.

I can also locate a bracket on the 80/20 extrusion to mount a space saver spare wheel, or a long range aux fuel tank if i wish.

Last job in the boot area is to make the panel to close off the battery compartment area.

On the LH side at back is mounted a Bluetooth AM/FM Radio & Player, Also 2 spare power supply circuits,1x direct battery power & 1x IGN switch power if required.

On the RH side at back is a Projecta 1600mah battery trickle charge unit with 240v power tail for easy battery maintenance between use.

A cover panel will seal off the battery compartment.

Cleaned up all the seams, filled with fibre reinforced filler and sealed with Auto Body Sealer to keep any water out.

Sprayed the inside of the boot cavity with Bed Liner paint.

The boot floor has holes in to fit over the rear bumper / quick jack mounts which are welded to the chassis members.

Covered the bumper mount holes with some aluminium sheet, cut to shape and then sealed around the mounting.

Everybody wants a piece of the action...

Made a template of the floor area from newspaper trimmed to shape, then cut from charcoal black marine carpet from Bunnings.

Radio mounted to the side of the boot compartment.

Battery charger hidden away behind the Roll Hoop Third Leg.

This pic also shows the single 400n gas strut and mounting to hold the boot lid open.

All done except for the Battery Compartment Cover.

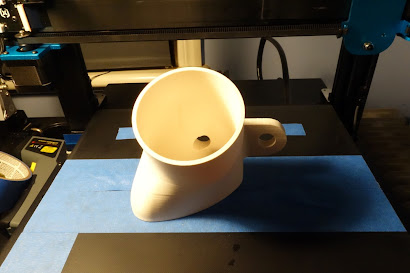

Milling up the mould for the fibreglass Battery Compartment Cover.

A bit of filling and sanding before sealing and a couple of coats of mould release agent.

Filed the lip off the number plate lamp location on the boot lid so the lamp and bracket sat flush and aligned.

Exposed a large air bubble under the gelcoat surface in he process, will fill with fibre reinforced filler before body coating is done.

All fitted up and aligned, just needs to have the gaps filed up to size.