Decided to create a custom Brake Cooling Duct system for the CR.

Several iterations of this Body Duct - Measure, Design, Print, Fit, re-design etc etc.

Final design fits to the chassis, fits over the Body inlet duct hole and has an aluminium stand off mounted to the body to aid support. The duct is common to LH or RH Vent.

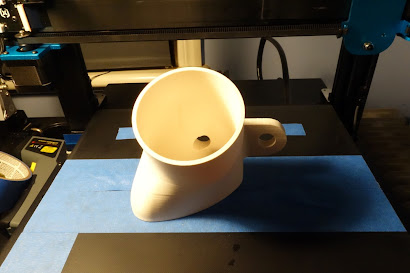

I printed the parts with Fibre Reinforced Fire Resistant ABS on an Artillery Sidewinder X1 V4 printer.

Finished print before a bit of cleanup.

The outriggers on the sides of the duct are for mounting.

In this pic, from inside the wheel arch shows the RH body duct mounted to the chassis with a crush clamp to protect the duct plastic from crushing, the duct fits over the vent moulded in to the body and is bolted on the RH side to a standoff post mounted to the body.

The wheel side duct went through many iterations of design changes, prints, fitting and adjusting to get the angles and clearance right.

The outrigger is the mounting point to the knuckle.

The wheel side duct is shaped to fit around the knuckle and direct air into the inside of the brake disk, painted in high temp paint and shielded with aluminium insulation foil, it has a 20mm air gap to the disc for added temperature relief.

The print filament is Fire Resistant ABS.

The duct is mounted to the knuckle mounting point with a longer M14 class 10 high tensile bolt, the duct fits to the bolt after the knuckle bolt nut is tightened and is secured with a separate lock nut.

Fit up excluding the disc shows the duct routing.

The duct is 3" dual silicon brake ducting.

The dual silicon wire wound duct is very heavy and stiff and I will be looking for a lighter less restrictive version. I do like the Red colour though. 😁

Pic from the front .