After considering the best way to cut and fill the manifold ports to match the LS3 heads, I've decided not to potentially ruin the inlet manifold and will make up some adapter plates.

10 or 12 mm Aluminium plate is all I will need to smoothly transition the ports without sacrificing cross sectional area.

This will lift the manifold vertically approx 12 to 14 mm depending on flange thickness.

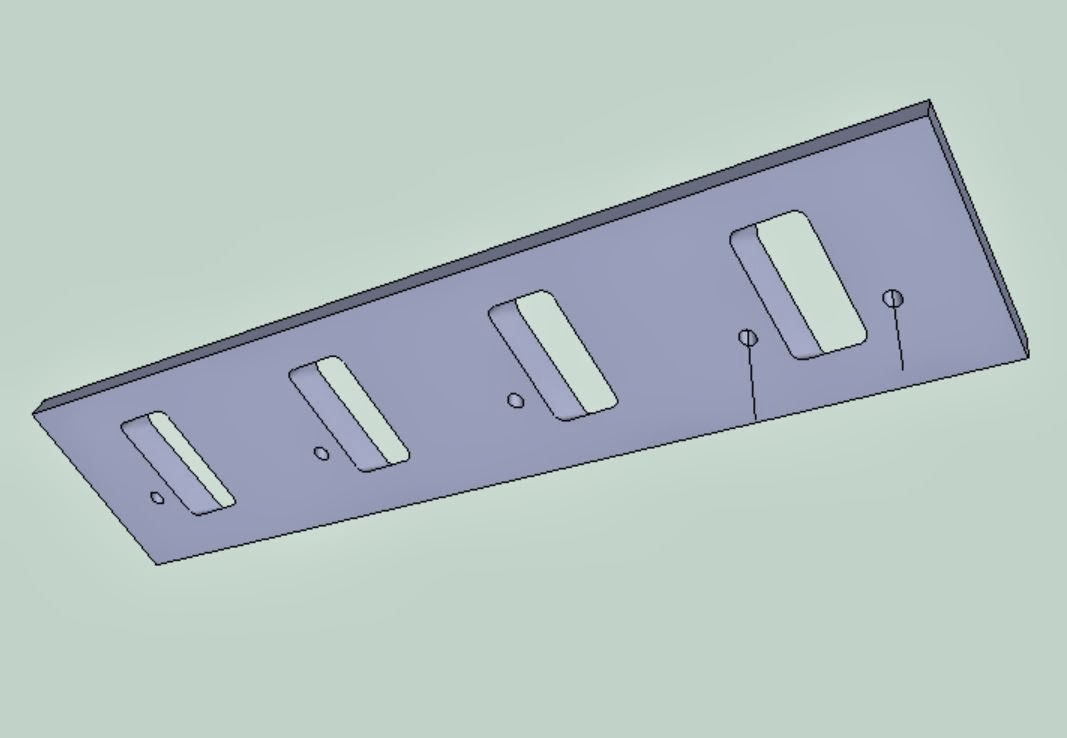

Here's some CAD pics of the concept.

From the Cathedral Port Side (Inlet Manifold)

From the Square Port Side (Head)

Picture showing the port walls morphing between

Cathedral profile and Square Port profile.

The port wall surface data is what I will use to create the machine tool path for the CNC Mill.

The far port wall in this pic you can see is an undercut, meaning i will have to cut a vertical wall on this side in the first pass, then flip the part on my machine to finish this tapered face profile.

The far port wall in this pic you can see is an undercut, meaning i will have to cut a vertical wall on this side in the first pass, then flip the part on my machine to finish this tapered face profile.